We like to add items to our quadcopter, drones, multirotors, whatever you want to call them.

The external plug location.

First off. Since most of us add a camera and gimbal to quads over 250mm, One of the problems we all run into on the CX20 is the location of the electrical connection on the belly. a slight modification opens up your options a lot.

When you have it together, carefully analyze where would work for you. Take pictures and pencil in some ideas. Then open it up and lets get to work.

Again, don't do ANY cuts until you have it open so you don't cut any wires.

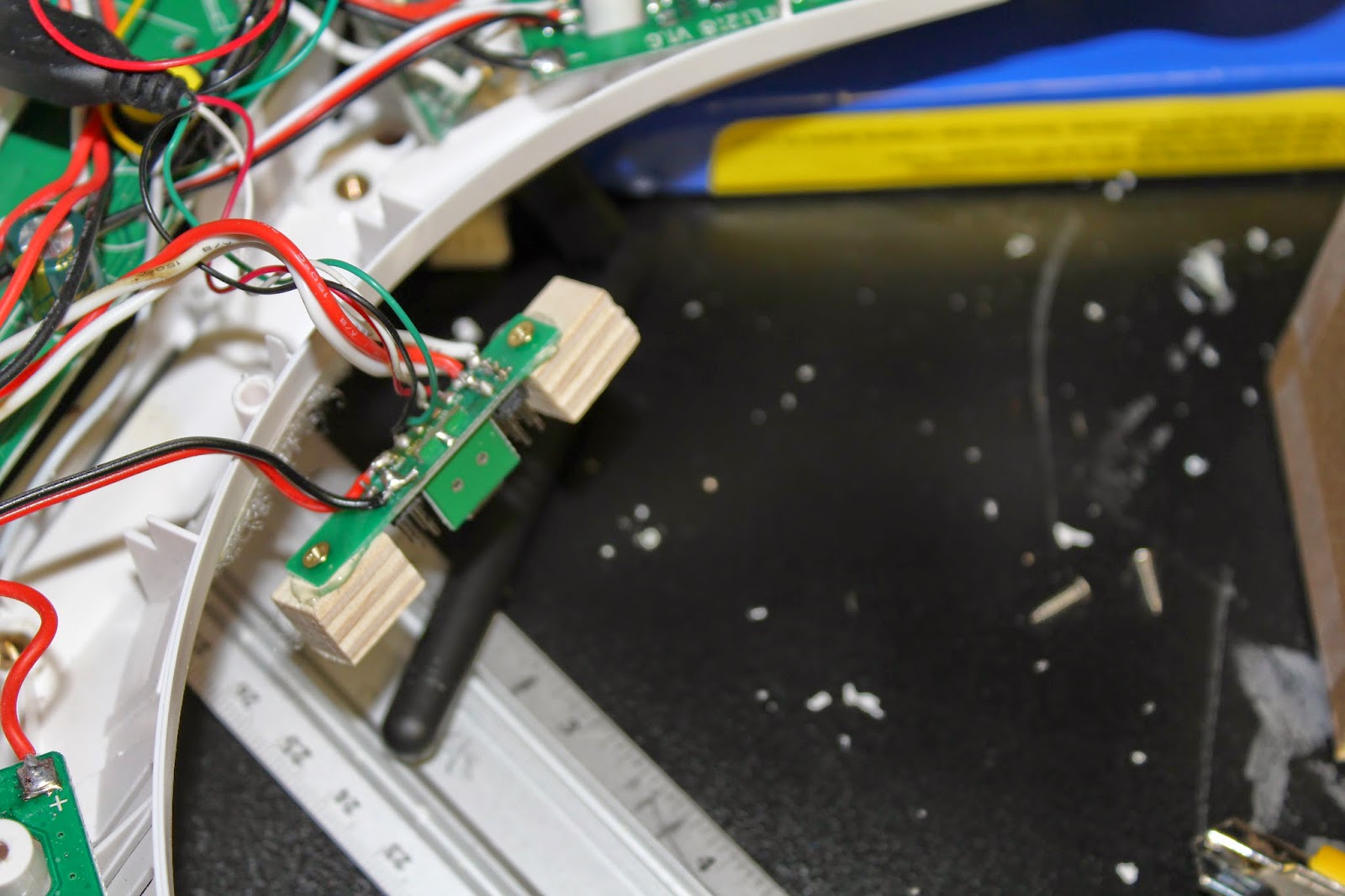

The plugs would have been sticking out if I attached the mini circuit board directly to the inside of the shell. so some 1/4" standoff blocks glued to the board and backed up with a single screw each. predrill to make it easier and prevent splitting.

The screws from inside that held the circuit board in place can be used on outside to hold it again (predrilled holes again. Make sure the board is centres so you can make all connections to the pins)

Now that the connections are relocated. The old hole in the belly, I glued a small bit of styrene plastic over the open hole in the belly to put some strength back (not shown in this picture)

Accessory sideboards

I was never happy with the FPV transmitter velcro attachment on the side

There are all sorts of options you can order. Some even made of carbon fibre. These can be great, but can be expensive and you have to use extra precautions working with it.

I decided to proceed with this project. It also lets me show you a

few interesting tidbits that might be unknown to some of you that I

learned in my days of Fixed wing R/C aircraft.

First off, I looked at the structure of the CX20. It is a plastic

shell design, Think of it like an exoskeleton. They entire structure

comes from the the shape and curves of the body. If you take a sheet

of thin cardboard, it's very flexible. No rigidity. Now if you bend

it twice and tape it together, it is a triangular tube. now it is

surprisingly strong. Some parts are in

compression

(squeezing) and some in

tension (pulling apart, like

pulling on rope). The other stress is

shear (This is

sort of like tearing). This is one of the basic principals of

engineering. Using the right materials to be in tension and which in

compression mean that you can combine several materials and the

result can be stronger than either. Bear in mind that a substance can

be hard but not strong, a substance can flex but be very strong.

The lightweight hobby grade plywood is great in

compression and to some extent tension, and fair in shear strength

but if you take a good general purpose aliphatic resin (wood glue or

Weldbond) and use it to bind

a single layer of fibreglass cloth to that plywood, the strength is

amazing, It is strong in tension and compression and in shear.

What I did here was to take some

Weldbond

glue and water it down 2 parts glue, 1 part water. This lets it

penetrate better into the cloth and the wood. It's probably not

necessary but i do like the results.

I put a sheet of cellophane down, then the wood (1/8" birch

plywood), apply a layer of the glue to the wood and lay the cloth on

it. Make sure the cloth extends past the wood a few CM (less chance

of the cloth falling apart). Work the cloth with some scrap cardboard

until the glue is covering and coming through the entire area. Flip

it over and repeat to create a double sided laminate. Cover this side

with cellophane as well (To smooth and contain any oozing). I put

this on a few sheets of newsprint (both sides, again to contain any

oozing). place this on a clean smooth surface and place another clean

smooth surface on top. Add weight then let this dry for 2 days. After

the 2 days, it will not be fully cured yet. take it out, carefully

remove the cellophane and let it continue to dry for another full

day. Cut away the excess cloth that is not supported by wood and you

have an amazingly strong homemade cheap composite panel. I cut of a

strip about 2 CM wide of this composite and a similar sized bit of

the 1/8" birch plywood without the glass cloth, then challenged

a friend to break them, the bare plywood broke with only slight

effort, The glass reinforced one he too 2 tries and notable effort to

break it, but it still was in one part, just lost most of it's

structure.

This finished composite cuts with little more effort than it did

before so it is very workable, it's very light and very strong.

I'll grant that its not as strong as as carbon fibre panels, but

it is still quite sufficient for many of our needs in this hobby.

The stock thumbscrews from the landing gear easily allow you to use them through these accessory plates.

I cut a large section out to allow access to the plugins

The FPV transmitter sits more securely with velcro holding it in place. A rubber band is cheap backup.